SERVO FD 10855 CP

Application

These cables are used in machine tools, industrial machineries, measurement control, and electrical applications. These are suitable for oily and wet areas within machinery and production shop floors that are subjected to normal mechanical stress. JZ-30400 P is resistant to contact with mineral oil based lubricants, diluted acids, aqueous alkaline and other chemical media. Outdoor use is possible within the indicated temperature range.

Standard

Requirement adapted to DINVDE 0245, 0281

Technical Data

Nominal Voltage : UO / U 300 / 500 V

Insulation Resistance : Min. 20 GΩ x cm

Temperature Range : Flexing -5°C to +70°C. Fixed installation -30°C to +70°C

Minimum Bending Radius : Flexing approx 12.5 x cable ø. Fixed installation approx. 4 x cable ø

Test Voltage : 4000V

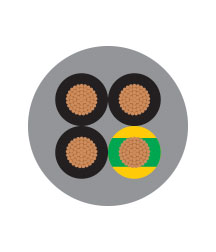

Cable Construction

Bare copper, fine wire conductors according to EN 60228 cl. 5.

Core insulation of special PVC TI2 EN 50363-3.

Black core with continuous white numbering according to DIN VDE 0293.

Cores stranded in layers with optimal lay-length.

Special polyurethane outer sheath (PUR).

Sheath color : Grey (RAL 7001).

Properties

Extensively oil resistant.

Abrasion and notch resistant.

Low adhesive surface.

Resistant to hydrolysis and microbes. UV resistant to ASTM G 154.

| Part Number | No. of Cores & Nominal Cross Sectional Area(Sq. mm) | Approx. Cable Diameter (mm) | Approx. Copper Weight (kg/km) | Approx. Cable Weight (kg/km) |

| 040100201050 |

2 x 0.5 |

4.8 |

.7 |

30 |

| 040100311050 |

3G 0.5 |

5.1 |

3.0 |

37 |

| 040100301050 |

3 x 0.5 |

5.1 |

3.0 |

37 |

| 040100411050 |

4G 0.5 |

5.6 |

7.4 |

46 |

| 040100401050 |

4 x 0.5 |

5.6 |

7.4 |

46 |

| 040100511050 |

5G 0.5 |

6.0 |

1.7 |

55 |

| 040100501050 |

5 x 0.5 |

6.0 |

1.7 |

55 |

| 040100711050 |

7G 0.5 |

6.7 |

0.4 |

72 |

| 040100701050 |

7 x 0.5 |

6.7 |

0.4 |

72 |

| 040101011050 |

10G 0.5 |

8.8 |

3.5 |

115 |

| 040101211050 |

12G 0.5 |

8.9 |

2.2 |

126 |

| 040101811050 |

18G 0.5 |

10.5 |

78.2 |

180 |

| 040102511050 |

25G 0.5 |

12.9 |

108.6 |

263 |

| 040103411050 |

34G 0.5 |

14.3 |

147.8 |

337 |

| 040104211050 |

42G 0.5 |

16.6 |

182.5 |

437 |

| 040100201075 |

2 x 0.75 |

5.3 |

13.0 |

39 |

| 040100311075 |

3G 0.75 |

5.6 |

19.6 |

48 |

| 040100301075 |

3 x 0.75 |

5.6 |

19.6 |

48 |

| 040100411075 |

4G 0.75 |

6.1 |

26.1 |

59 |

| 040100401075 |

4 x 0.75 |

6.1 |

26.1 |

59 |

| 040100511075 |

5G 0.75 |

6.9 |

32.6 |

76 |

| 040100501075 |

5 x 0.75 |

6.9 |

32.6 |

76 |

| 040100711075 |

7G 0.75 |

7.6 |

45.6 |

97 |

| 040100701075 |

7 x 0.75 |

7.6 |

45.6 |

97 |

| 040101011075 |

10G 0.75 |

10.0 |

5.2 |

156 |

| 040101211075 |

12G 0.75 |

10.1 |

8.2 |

171 |

| 040101811075 |

18G 0.75 |

11.9 |

17.3 |

247 |

| 040102511075 |

25G 0.75 |

14.6 |

63.0 |

357 |

| 040103411075 |

34G 0.75 |

15.7 |

21.6 |

446 |

| 040104111075 |

41G 0.75 |

17.4 |

67.3 |

543 |

| 040100200001 |

2 x 1 |

5.6 |

17.4 |

46 |

| 040100310001 |

3G 1 |

6.0 |

26.1 |

59 |

| 040100300001 |

3 x 1 |

6.0 |

26.1 |

59 |

| 040100410001 |

4G 1 |

6.8 |

34.8 |

77 |

| 040100400001 |

4 x 1 |

6.8 |

34.8 |

77 |

| 040100510001 |

5G 1 |

7.5 |

43.5 |

93 |

| 040100500001 |

5 x 1 |

7.5 |

43.5 |

93 |

| 040100710001 |

7G 1 |

8.9 |

60.8 |

132 |

| 040101010001 |

10G 1 |

10.8 |

86.9 |

191 |

| 040101210001 |

12G 1 |

11.1 |

104.3 |

215 |

| 040101810001 |

18G 1 |

13.2 |

156.5 |

311 |

| 040102510001 |

25G 1 |

16.2 |

217.3 |

452 |

| 040103410001 |

34G 1 |

18.1 |

295.5 |

587 |

| 040104110001 |

41G 1 |

19.7 |

356.4 |

700 |

| 040100201105 |

2 x 1.5 |

6.3 |

25.5 |

61 |

| 040100311105 |

3G 1.5 |

6.7 |

38.2 |

78 |

| 040100301105 |

3 x 1.5 |

6.7 |

38.2 |

78 |

| 040100411105 |

4G 1.5 |

7.3 |

50.9 |

98 |

| 040100401105 |

4 x 1.5 |

7.3 |

50.9 |

98 |

| 040100511105 |

5G 1.5 |

8.2 |

63.7 |

123 |

| 040100501105 |

5 x 1.5 |

8.2 |

63.7 |

123 |

| 040100711105 |

7G 1.5 |

9.0 |

89.1 |

160 |

| 040100701105 |

7 x 1.5 |

9.0 |

89.1 |

160 |

| 040101211105 |

12G 1.5 |

12.1 |

152.8 |

280 |

| 040101811105 |

18G 1.5 |

14.5 |

229.2 |

412 |

| 040102511105 |

25G 1.5 |

17.2 |

318.3 |

576 |

| 040103411105 |

34G 1.5 |

19.6 |

432.9 |

766 |

| 040104111105 |

41G 1.5 |

21.3 |

522.0 |

915 |

| 040100201205 |

2 x 2.5 |

7.6 |

42.4 |

93 |

| 040100311205 |

3G 2.5 |

8.3 |

63.7 |

124 |

| 040100411205 |

4G 2.5 |

9.1 |

84.9 |

157 |

| 040100511205 |

5G 2.5 |

10.2 |

106.1 |

196 |

| 040100711205 |

7G 2.5 |

11.2 |

148.5 |

256 |

| 040101211205 |

12G2.5 |

14.8 |

254.6 |

443 |

| 040100410004 |

4G 4 |

10.8 |

135.0 |

234 |

| 040100510004 |

5G 4 |

12.1 |

168.7 |

292 |

| 040100710004 |

7G 4 |

13.3 |

236.2 |

383 |

| 040100410006 |

4G 6 |

13.0 |

202.4 |

345 |

| 040100510006 |

5G 6 |

14.5 |

253.1 |

430 |

| 040100710006 |

7G 6 |

16.0 |

354.3 |

566 |

| 040100410010 |

4G 10 |

15.5 |

344.7 |

539 |

| 040100510010 |

5G 10 |

17.1 |

430.8 |

666 |

| 040100710010 |

7G 10 |

19.0 |

603.2 |

888 |

| 040100410016 |

4G 16 |

18.8 |

574.1 |

852 |

Note : * G = With green / yellow earth core , X = Without green / yellow earth core