UL 1007

Application

These cables are used for internal wiring of switchboards, electronic and electrical equipment, e. g. households, radio of televisions,

monitor and control desks.

Standard

UL - Std. 758 , CSA C 22.2 No. 210

Technical Data

Nominal Voltage : 300V

Test Voltage : 2000V

Test Voltage (Spark Test)

AWG 26-20 : 4kV, AWG 10 -18 : 5kV

Temperature Range : Flexible -5°C to +80°C. Fixed installation -20°C to + 80°C

CSA - AWM I A/B

Temperature at Conductor : Max. UL and CSA : +105°C

Bending Radius : Flexing 10 x cable ø. Fixed installation 5 x cable ø

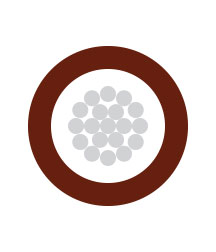

Cable Construction

Annealed plain or tinned stranded copper conductor.

PVC - core insulation according to UL - Standard 1581, Class 43 Tab. 50.182, heat and damp resistant.

Properties

Conditionally resistant to oils, solvents, acids and dyes.

PVC self - extinguishing and flame retardant, test method to UL VW-1 and CSA FT 1 / FT 2

Cable Design Parameters

Kindly complete the part numbers for these cables by adding the suffix (in place of ‘xx’) for the insulation colour required:

01 – green, 02 – black, 03 – red, 04 – blue, 05 – yellow, 06 – green/yellow, 07 – white, 08 -Violet, 09 – brown, 10 – orange, 11 – pink, 12 – grey, 13 – light blue.

| Part Number | AWG No. | No. of Cores & Nominal Cross Sectional Area (Sq. mm) | Approx. Cable Diameter (mm) | Approx. Copper Weight (kg/km) | Approx Cable Weight (kg/km) |

| 06030101xx30 |

26 |

1 x 0.14 |

1.3 |

1.4 |

3.0 |

| 06030102xx30 |

24 |

1 x 0.21 |

1.5 |

2.1 |

4.3 |

| 06030103xx30 |

22 |

1 x 0.33 |

1.6 |

3.5 |

5.8 |

| 06030104xx30 |

20 |

1 x 0.52 |

1.9 |

5.2 |

8.0 |

| 06030105xx30 |

18 |

1 x 0.82 |

2.2 |

8.3 |

12 |

| 06030106xx30 |

16 |

1 x 1.32 |

2.5 |

13.5 |

18.4 |